|

�@

�@ �@ |

|

||||||||||||||||||||||||

|

Topsøe

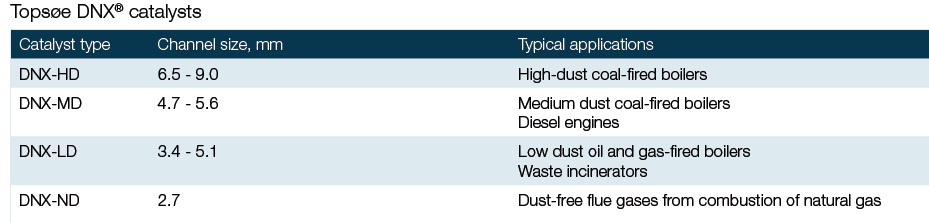

The Topsøe DNX® catalysts are of the corrugated type and are produced in 10 different channel sizes to cater for different dust content of the process gas and 10 different chemical compositions are available to ensure optimal operation for each individual application. Today the Topsøe DNX® catalysts are installed in a long range of different applications such as ��

Coal-, oil-, gas- and biomass-fired utility boilers Catalyst features High catalyst activity

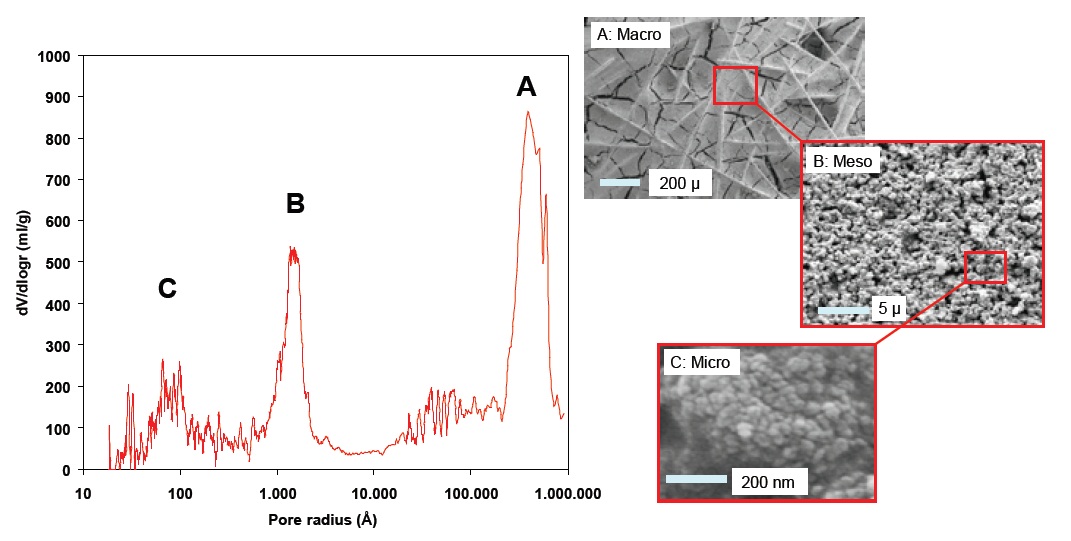

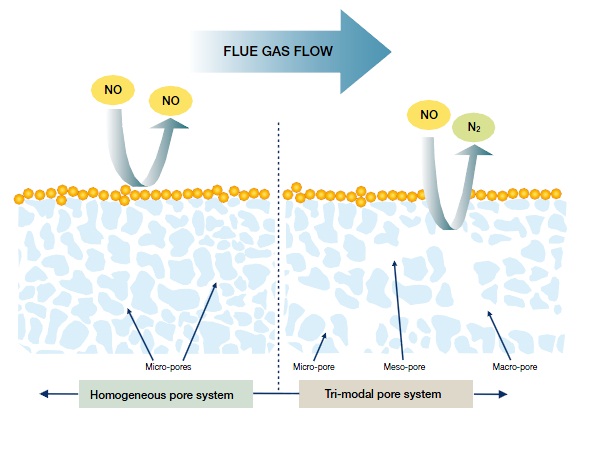

DNX® pore-size distribution. The three pore-size regimes - A: Macro-pores, B: Meso-pores, C: Micro-pores - are visualised by scanning electron microscopy (SEM). �@ Very low SO2 oxidation The low SO2-oxidation activity has been demonstrated and SO2 oxidation rates down to 0.1% have been designed for and guaranteed in coal-fired power plants. Very high poison resistance Data have demonstrated that even with several per cent of poisonous constituents accumulated in the catalyst, it remains active. The presence of macro-pores also ensures access to the active catalyst sites even when burning coals with a high calcium content. High resistance to thermal and

mechanical shocks Catalyst elements and module

design

�@ Topsøe SCR DeNOx�ʤƾ���Ѥ�����ƶt�㦳���@���O

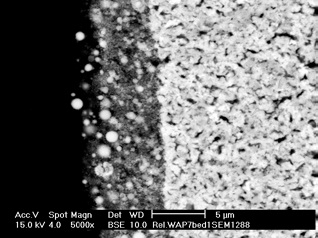

High content of calcium in coal

can cause deactivation of the catalyst in the SCR unit. The scanning

electron microscopy picture shows a typical fouling layer on the

catalyst surface seen �@

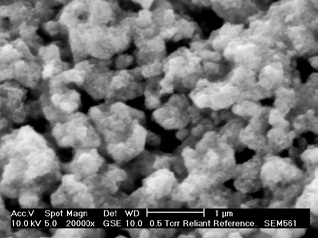

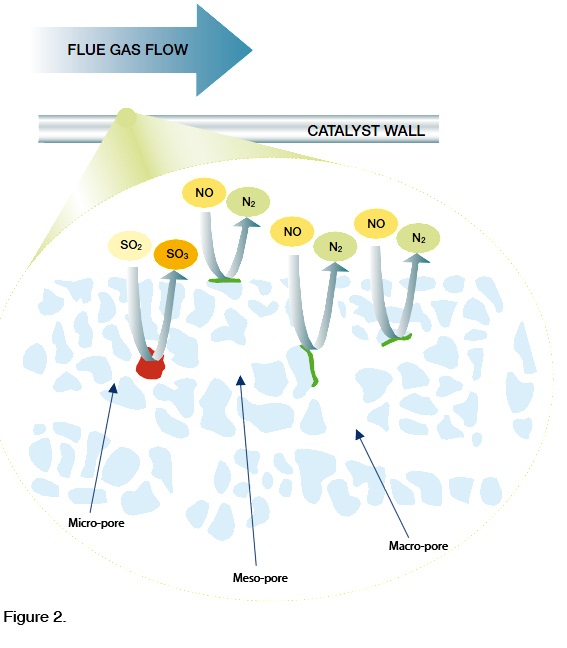

Scanning electron microscopy picture of catalyst surface before and after exposure in an SCR unit firing high-calcium PRB coal. The photo to the right shows a dense fouling layer of amorphous calcium sulphate. Pore plugging is observed in combination with a fine deposit of sub-micron fly ash particles. �@ Unique pore structure This very unique pore structure of Topsøe��s DNX® catalysts is a result of careful selected titania raw materials combined with several controlled drying and calcination processes in the fullyautomated catalyst manufacture. �@ Figure 2.

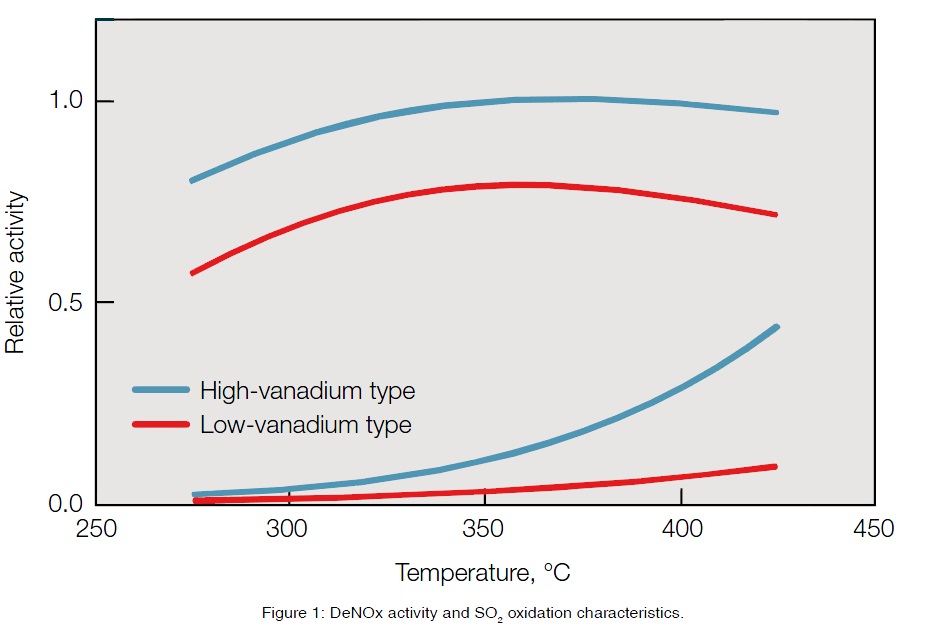

The tri-modal pore structure further results in a high resistanceto other poisons like arsenic while at the same time providing thelowest SO2 oxidation on the market. Proven experience The large-size pores, macro-pores, serve to ensure access to the active interior of the catalyst even if large amounts of poisons have been deposited on the catalyst. They further enhance gas-phase diffusion of NOx and ammonia into the catalyst and thereby the overall catalyst activity. The presence of medium-size pores, meso-pores, ensures an efficient internal distribution of the reactants to the immense network of micro-pores which provide a very high active surface area necessary for the catalyst activity. �@ Topsøe SCR DeNOx �ʤƾ�SO2 ��Ƭ�SO3����Ʋv

Figure 1: DeNOx activity and SO2 oxidation characteristics. �@

As illustrated in Figure 2 the DeNOx reaction takes place on the internal surface in the pores of the catalyst and, by some approximation, the activity (ADeNOx) becomes (1) ADeNOx = k1 �� As �� Ca �� �b where As is the specific active surface area (m2/m3), C is the percentage of vanadium in the catalysts and �b is the effectiveness factor accounting for the resistance towards diffusion of NOx and ammonia to the catalyst active sites. In contrast, the oxidation of SO2 is not limited by diffusion and thus takes place in the entire catalyst mass and we get (2) ASO2 = k2 �� W �� C where ASO2 is the activity towards SO2

oxidation and W is the bulk density of the catalyst. (3) ASO2/ADeNOx = k �� W/As �� C1-a �� �b-1 The special way of manufacturing the Topsøe DNX® catalyst allows for careful control of the pore structure within the catalyst and this has been optimised with a tri-modal pore structure as shown in Figure 2. Through large macro-pores in addition

to the meso- and micropores the access to the interior of the catalyst is

enhanced and this maximises the effectiveness factor �b. The elaborated pore

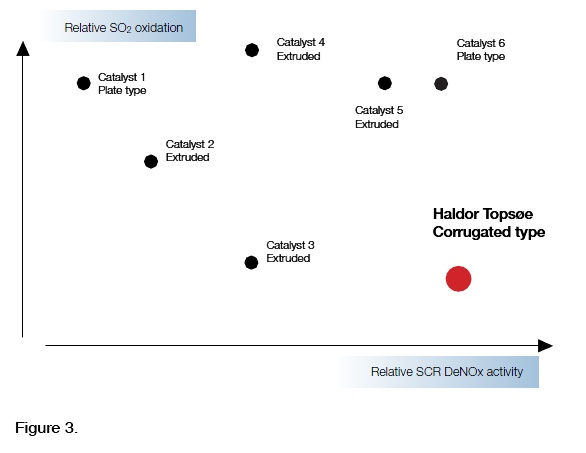

The low SO2 oxidation of the Topsøe DNX® catalyst has been verified by testing in the industry. Figure 3 illustrates such a comparison where standard extruded catalysts and plate-type catalysts with a much lower porosity show a much inferior ratio between SO2 oxidation and DeNOx activity than Topsøe��s DNX® catalyst. Topsøe is capable of tailor-making catalysts for any application and for any level of sulphur in the fuel and can therefore provide the best compromise between NOx removal and SO2 oxidation. Topsøe has demonstrated superior performance together with low SO2 oxidation under industrial conditions and has provided guarantees for SO2 oxidation down to 0.1%. �@ |

|||||||||||||||||||||||||

|

|||||||||||||||||||||||||

| �@ | �@ |

�_�ϪA�ȹq�ܡG 02-27116284 FAX�G02-27116285 �n�ϪA�ȹq�ܡG 05-6914381 FAX�G05-6917752 �̨��s�����A�G�ù��ѪR��1024x768 |

|||||||||||||||||||||||

Haldor

Topsøe is a leading supplier of SCR DeNOx catalysts, which are tailored

to suit a comprehensive range of applications.

Haldor

Topsøe is a leading supplier of SCR DeNOx catalysts, which are tailored

to suit a comprehensive range of applications.